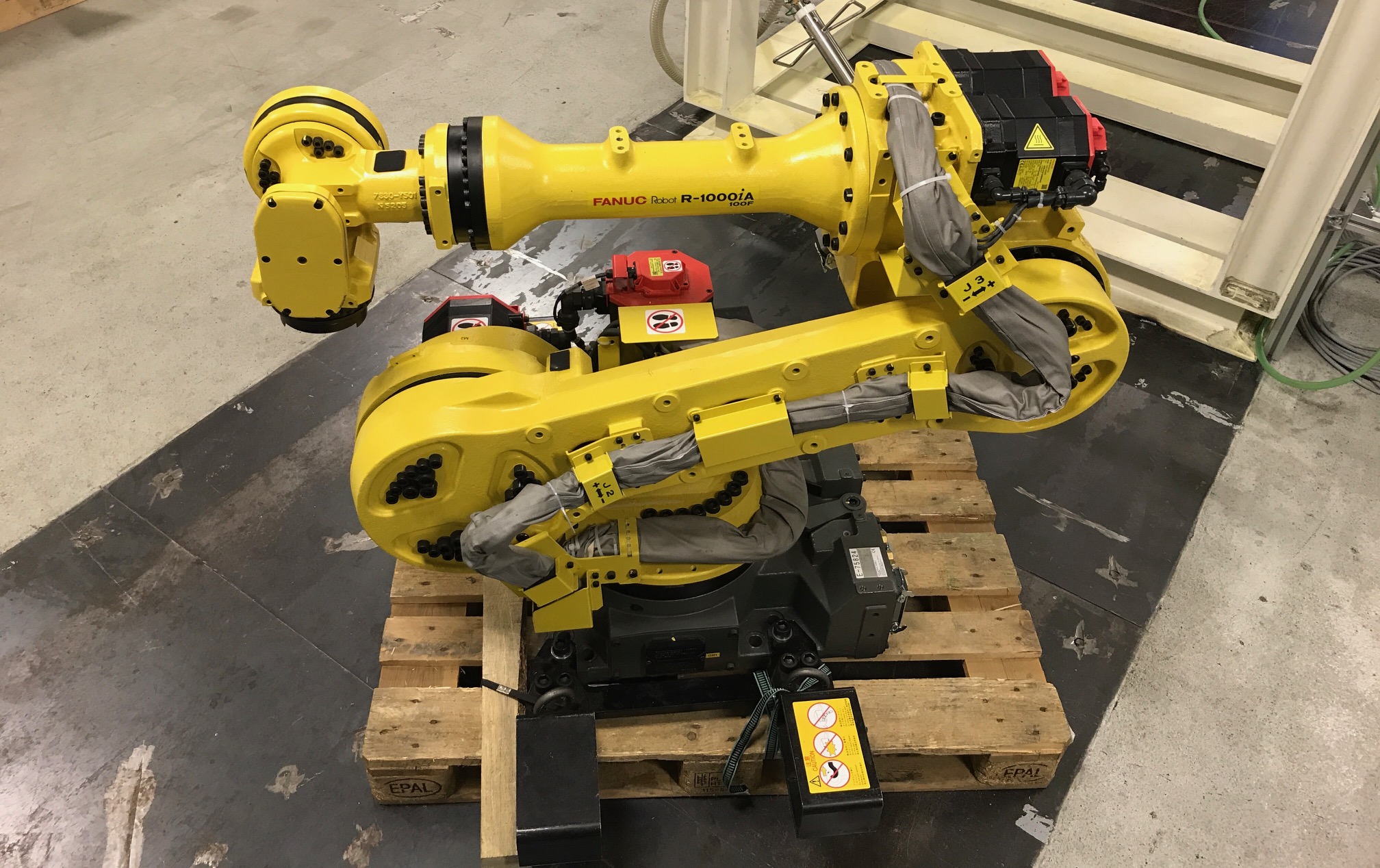

Robot from Fanuc is here!

Welcome R-1000iA/100F

This 6-axis robot has been designed with flexibility to perform any challenging tasks. It is very fast and achieves long cycle times, which is particularly suitable for a wide range of high speed spot welding applications. We are looking forward to test all qualities mentioned above.

Keep an eye on us and we let you know our progress with the new project!